Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

PRODUCT

Sheet metal equipment one-stop manufacturing supplier

TECHNOLOGY

Sheet metal equipment one-stop manufacturing supplier

ABOUT

Sheet metal equipment one-stop manufacturing supplier

Shandong Jiayi Machinery Co., Ltd.

Shandong Jiayi Machinery Co., Ltd. was established by Shandong Luzhu Group Co., Ltd.and Jiayi Machine Tool (Shanghai)Co., Ltd, and completed the completion of the wholly-owned acquisition of Italian LAG and Rainer brand, trademark, process tec-hnology and marketing network. LAG International Equipment Production Base. LAG international absorbs many years innovation experiences of the Italian for the sheet metal industry technology.pay attentionto the detail, design and the perfect combination of the huge Chinese productivity, and plus the world's top-class components withmany others advantages, make LAG become to the best supplier in the sheet metal industry, integrated customization industrial 4.0,industrial software development, system integration of production, sales and service. Shandong Jiayi Machinery Co., Ltd.is equipped with advanced mechanical machining machines at home and abroad, including3 Italian MECOF 360°rotary heads,5 axes linkage floor boring and milling machining centers, and 6 sets of 5-axes gantry machiningcenters with 360° side milling heads. More than 10 sets of machining centers; supporting more than 70 sets of international advancedprocessing machines such as CNC lathes, milling machines, grinding machines, wire cutting, vigorous milling machines, flame cutt-ing, plasma cutting machines, large presses, and plate normal furnaces. Specializing in the production of world-class precision CNCbending machine, shearing machine, CNC punching machine and other sheet metal processing equipment, to create LAG Internatio-nal's cutting-edge technology brand. The company fully meets its assembly needs, produces and sells complete machine products, and utilizes the superiority of mach-ining equipment to provide various types of precision machining parts to high-end equipment manufacturers at home and abroad. Atthis stage, it has been supplied to high-end machinery manufacturers such as MECOF, SISTEC, NDMK,Shandong Taikai Robot, andShandong Tide.

More+CHOOSE US

Sheet metal equipment one-stop manufacturing supplier

NEWS

Sheet metal equipment one-stop manufacturing supplier

Electrical manufacturing industry solutions

Industry pain points: - The bending process is complex, the workpiece size is large and the size is uncertain. - The weight of the sheet is heavy, and the number of bending workers requiring experienced skills is large and the labor intensity is high. - Customer customized products show the characteristics of small batch, many batches, and many size changes. Solution:Typical workpieces in the electrical industry, the left and right side panels, top plates, backplanes, panels, etc. of KYN28 cabinets, and the size and size are relatively uncertain according to customer orders, and the bending process needs to press the edge, double folding, turning over, bending and other work. Manual bending requires more than two bending machines, one crushing edge, one bending, two bending machines need 3-4 people to operate, 8-10 minutes to complete a piece.

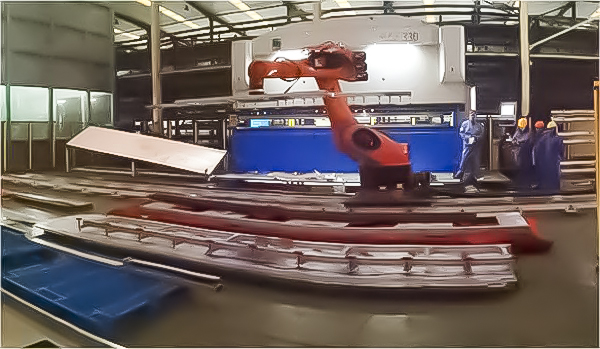

Construction machinery manufacturing industry solutions

Industry pain points:- The workpiece is heavy, difficult to bend and variable in size. - Manual bending requires 4 bending machines and 8 operators to complete step by step, high scrap rate Solution:Lag-geshe calculates the machining time of each workpiece by analyzing the computer 3D simulation of the bending workpiece of the customer. From the workpiece automatic feeding, automatic centring, bending, bending step, automatic turning, automatic cutting, automatic palletizing for all aspects of the solution. The quantity of the workpiece gripper and bending die is put forward. Advanced guarantee is provided in the application software of bending unit. A breakthrough has been made in the development and application of special functions of bending unit, such as automatic edge finding and automatic deflection compensation.

MORE+

Aluminum veneer curtain wall manufacturing industry solutions

Industry pain points: - The built-in hook plate requires high bending accuracy and large scrap rate. - Large surface size, manual lifting is difficult; Manual bending capacity is low. - The model is complex, the shape size often changes irregularly, and the management of on-site material palletizing and transferring is difficult. Solution:Lag-geshe calculates the processing time of each workpiece through computer 3D simulation analysis of the bending workpiece of the customer. From the workpiece automatic feeding, automatic centring, bending, bending step, automatic turning, automatic cutting, automatic palletizing for all aspects of the solution. The quantity of the workpiece gripper and bending die is put forward. Advanced guarantee is provided in the application software of bending unit. A breakthrough has been made in the development and application of special functions of bending unit, such as automatic edge finding and automatic deflection compensation.

MORE+

Automotive manufacturing equipment industry solutions

Industry pain points:-6 meters long door plate needs folding head (short side bending),- The workpiece is heavy, the number of operating workers is large, and the labor intensity of workers is large. - Variable size, small batch.Solution:Lag-geshe calculates the processing time of each workpiece through computer 3D simulation analysis of the bending workpiece of the customer. From the workpiece automatic feeding, automatic centring, bending, bending step, automatic turning, automatic cutting, automatic palletizing for all aspects of the solution. The quantity of the workpiece gripper and bending die is put forward. Advanced guarantee is provided in the application software of bending unit. A breakthrough has been made in the development and application of special functions of bending unit, such as automatic edge finding and automatic deflection compensation.

MORE+

R&d and manufacture of large tonnage equipment

The Italian customer purchased the 800T-8000 large-tonnage bending machine produced by Geshe Technology, which has been used for more than 10 years and is still in normal operation. Geshi's technology and quality have been trusted by customers, and an order of 1400T-9000 is under discussion and signing.

MORE+

Telephonee:

+86 13705384901

Build Geshi international technology brand

CONTACT US

Tel:+86 13705384901 +86 18953813118 +86 0538-6089096 +86 0538-6089189

E-mail:[email protected]

Add:South of Kuixing Road, north of Xingfu Road, Ciyao Town, Ningyang County, Tai'an City, Shandong Province, China